Overview

Exatron has long supported the power device industry by offering handlers built specifically for power device packages. In addition, Exatron has been integrating the high power testers associated with power devices for over fifteen years.

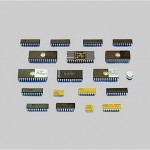

As you will see from the photograph on this page, Exatron has supported a wide variety of power package types -- and this photo is hardly exhaustive. Given our expertise in manufacturing systems for custom applications, we can say that to date we have not seen a package we could not handle.

Exatron offers power device handing in both of our primary gravity feed handler families: the 3000B and the 5000. For multiple test sites, such as that pictured on this page, the 5000 is the handler of choice.

In order to facilitate proper testing, Exatron offers standard or true Kelvin contact sets, in standard or custom dimensions in order to assure proper contact with leads, lugs, contact bars, etc.

All high-power test applications include safety covers with magnetic interlocks. In most cases, the interlock wiring can be routed straight into the tester itself to assure no high voltage test signals will be sent while the cover is removed.

Options

Many options are available for the Model 5000 Handler, most of which may be added in the field:

- Laser Marker Upgrade

- High Frequency Contacts - Particle Interconnect

- Elevated Temperature Handling and Testing

- Tape & Reel Output Method

- Multiple Test Sites

We have a combination of multiple test sites to match your requirement! Available with one or more test sites, the 5000 Series is ideal for applications with multiple test requirements, high volume requirements, elevated temperature requirements, or for automating the programming and testing of PLDs. Throughput can be doubled with a multisite handler!

| Ambient | Elevated Temperature |

| Room Temperature | Up to 155°C |

| 1,2,3, 8 or Custom Test Sites | 1, 2, 3 or Custom Test Sites |

| Dead or Live Bug | Dead or Live Bug |

- Automated Tube Unloader

Exatron can provide an automated tube unloader that can accept up to 60 tubes and automatically unload them into the handler system. - Bowl-feed Input

Exatron can integrate most types of bowl-feeding equipment with our handling equipment. - Output Tray

For small, fine pitch devices or devices which must be protected against "slamming" into the bottom of a tube, Exatron manufactures a line of output "trays" for our gravity feed systems. These trays are fixed output rails made specifically for a given type of device. These rails can be built with special features to retard the fall of the devices through the rail and prevent one part from slamming into another. Output trays come with spring-loaded gates and specially designed ports for an operator to insert a plastic shipping tube and fill that tube from the output tray rail. - Opto-isolation Interface

Exatron offers an opto-isolation interface option for electrically "noisy" applications - Light Pole Status Indicator

Exatron offers a three-color light pole status indicator to provide quick visual updates on handler performance to operators. This facilitates operation of multiple pieces of equipment by single operators. - Aluminum Output Tubes

Exatron highly recommends the use of aluminum output tubes for tube-fed devices. These tubes have several advantages, including reduction of ESD concerns, reduction of handler jams, and ease of change-over for handler kits. For more information click here. - Service Contract

- Other Options Available as Requested