Overview

Exatron offers a dedicated MSOP (Mini Small Outline Package) device handlers. These devices are unique in the industry due to their small size and near-square dimensions. These features, along with the proportionally more serious problem associated with mold flash in devices this size, presented Exatron with very serious challenges in building a handler.

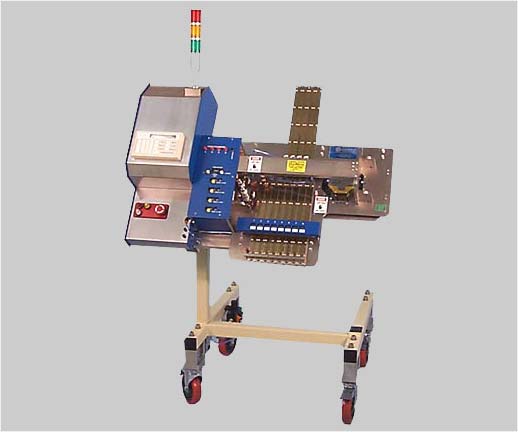

The answer is a hybrid of standard gravity feed handling with features of pick-and-place mechanisms. The Exatron MSOP handler incorporates a single servo-motor driven pick up head to take devices from an input magazine (designed to be loaded off line), present them to a test site, and then return them to the top of an "output tray." The system has only one axis of linear movement (not counting the Z-axis plunge to board test site) and the devices never have to cross a gap or threshold between tubes.

The unique singulation method employed to both singulate and precise devices in the input magazine facilitates picking up and placing down the devices. In addition, precisely machined pick up heads help to assure proper device placement.

The MSOP handler shares electrical interfaces with all other Exatron Model 5000 handlers, and it is designed to dock to a wide variety of large and small test heads.

At this point, there are no options available for the MSOP handler with the exception of additional magazines to be loaded off-line and customized test sites.

Operation

The operation of the MSOP handler is similar to and substantially different from a standard Exatron Model 3000 or Model 5000 gravity feed handler.

The input of the MSOP handler is a removable "input tray" with trackwork machined into the plate. Thin metal plates then bolt onto the input tray plate to cover the tracks and create the "tube" through which the devices will flow.

The input plate is designed to be removed from the handler and loaded off-line at an operators station. Due to their almost square aspect ratio, the MSOP devices have a very bad habit of turning in their tubes (this is particularly true of plastic shipping tubes). The input tray is designed for the operators to have access to the trackwork so that any device which may have turned can be coaxed back into position with a pair of tweezers or other appropriate probe.

The operator loads the input tray into the system, and closes the safety cover which encloses the entire mechanism of the handler. Handler controls are similar to those found on Exatron Model 5000 and Model 3000 handlers.