AUDIO TEST

AUDIOTEST1

Four-tray input & output | Dual pickup heads | Small footprint

AUDIOTEST2

Dual pickup assembly carries 16 devices | Loads 2 groups of 8 devices each

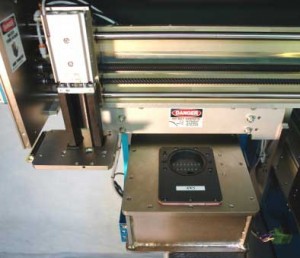

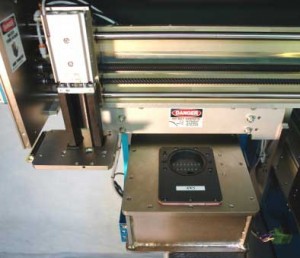

AUDIOTEST3

Audio test head | Sound-tight test chamber

AUDIOTEST4

Audio test head over test sockets | Multiple devices tested in parallel

LASER MARKING AND INSPECTION OF AUDIO SENSORS

LASER MARKING AND INSPECTION OF MEMS CAPACITORS

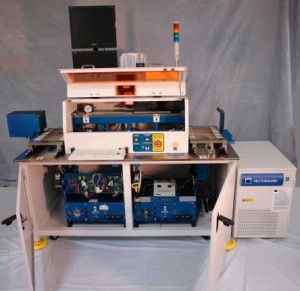

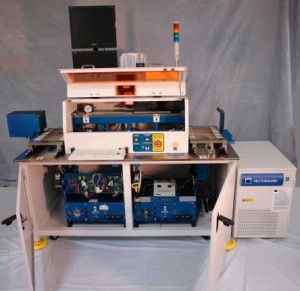

CAPACITORS1

Strip magazine input/output tables | Fully enclosed | Handler control | Dual monitors

CAPACITORS2

Handler PC on left | Machine vision PC on right | Laser PC in OEM cabinet

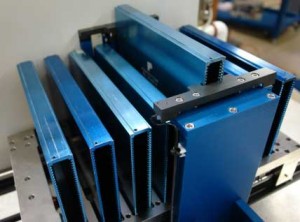

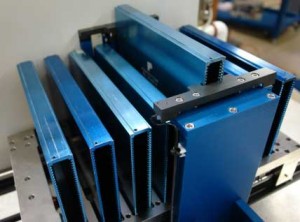

CAPACITORS3

Multiple strip types marked & inspected by same handler | 40 strips per magazine

CAPACITORS4

Movable table holds 8 magazines

CAPACITORS5

Strip at laser mark site

CAPACITORS6

Strip at inspection site

LASER MARKING AND INSPECTION OF DLP (DIGITAL LIGHT PROCESSING) CHIPS

DLP

JEDEC-tray laser marker | Tray stackers in left cabinet | Laser marking & inspection in right cabinet

DLP1

In-tray inspection & marking at same position | Machine vision: Finds location of each device - Aligns laser mark to each device - After marking, verifies 2D bar code

DLP3

Laser: Device starts with ink mark - Ink mark is "erased" by laser - Device is laser marked

DLP4

In-line Exatron Peregrine programmer

DLP5

Peregrine programmer makes contact directly to devices in JEDEC tray

LASER MARKING AND INSPECTION OF AUDIO SENSORS

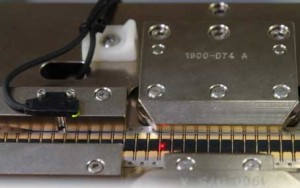

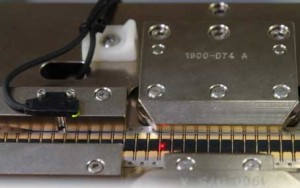

AUDIOLASER1

Dual cameras Read bar code from card bottom Laser mark bar code on each device on card top side Verify bar code mark

AUDIOLASER2

Small footprint