KEY FEATURES:

- 25" (63.5 cm) W by 28” (71 cm) D by 21.5" 55 cm) H (With standard 24" gantry. 30" gantry available.)

- 2 JEDEC trays

- Single test site standard. Dual sites available.

- Handles devices 1.6 x 1.6mm to 60 x 60mm*

- *requires an additional hold down cylinder

- *1.6 x 1.6mm to 25 x 25mm with thermal options (up to 60 x 60mm with additional hold down cylinder)

- Handles all SMD and leaded device types

- Near zero mechanical adjustment or change over kits

- User-friendly Windows 10-based GUI

- Software configurable binning

- Servomotor/PC controlled device placement and contact force

- Double stack protection

- Continuous automated retest

- Dino-lite calibration camera ensures precise alignment

SPECIFICATIONS:

| Device Types | BGA, CSP, DIP, Flat Pack, LCC, LGA, MSOP, PCB, PGA, PLCC, QFN, QFP, SIMM, SIP, SIMM, SODIMM, SOIC, SSOIC, TSSOP, and custom devices |

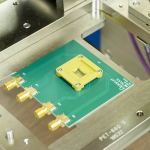

| Test Sockets | Supports nearly all OEM test sockets; Exatron custom built spring probe sockets, Exatron Particle Interconnect (PI) RF and CSP sockets |

| Jam Rate | 1/5000 when using Exatron-built test sockets |

| Tray | 2 JEDEC trays, fits all formats, 2" and 4" waffle packs, input and output tube trays, Handler tray carriages equipped with small volume "bucket" for additional sort capability |

| Binning | Up to 8 sorts standard, output tray sort mapping; drop to bucket standard |

| Contact Force | 0-20 lbs standard, software controlled up to 100 lbs with thermal options or additional hold down cylinder. |

| Tester Control Interface | TTL/opto isolated; RS-232; GPIB; Ethernet |

| Tester DUT/Socket Board | 8" under side of board clearance; up to 18"x 18" square with centered socket; many mounting options |

| Operator Interface | Widows 7 user interface; data log file generation software standard |

| Remote Control | Internet access standard; remote training, troubleshooting, and service standard |

| Dimensions and Weight | 25” (63.5 cm) W by 28” (71 cm) D by 21.5” 55 cm) H (excludes light pole); under 100 lbs |

| Facilities Requirements | 100-240 VAC 50/60 Hz, 80 PSI @ 2 CFM Clean Dry Air (CDA), Internet connection (NOTE: For standard applications upgrade is available allowing no additional required air supply for customers with no CDA available) |

| Vision Assist | Standard built-in camera assists in set up of new devices |

| Double Part Protection | Standard built-in vacuum sensor checks for empty socket at start of job and checks every pick and place during operation |

| Mechanical Precisor Ready | Built-in controls for many possible precisor options |

CHANGEOVER KIT: Near kit-less changeover:

- Change the pickup tip (if needed, no tools required)

- Change out the test socket

- Load new JEDEC trays

- Load a previously set up JOB file and run next test

All mechanical changeover adjustments are software-controlled with standard setup. TEMPERATURE UPGRADES:

- Single temp. test site (requires 30" gantry)

- (-75°C) -55°C - 155°C (+175°C) test capability

MEDIA UPGRADES: (May required additional gantry length)

- Detaper input

- Exatron-built tape and reel output

- Small volume tube to tube

- Bucket output

VISION UPGRADES: (May required additional gantry length)

- Top-side OCR camera (for serialized device testing)

- Bottom-side 2D and 3D-lead inspection options (requires table option)

MARKING UPGRADES:

MOUNTING UPGRADES:

- Table top mount standard

- Many welded steel table options

- Built-in lift options allow effortless handler movement

See more on Exatron Model 900 pick and place handlers